Sunday 10/5 9:30 a.m.

Saturday 10/4

Rosilene estimates we will harvest 40 yellow bins, producing about

170 bottles of wine.

Sunday 10/5 9:30 a.m.

Cleaned equipment and boxes again to resume picking.

No activity yet in the two PFCs.

10:45 Washing completed, so headed up to vineyard.

Dumped the 4.5 gallons from last night into the 44 gallon container from Brian.

(15.5 gallons)

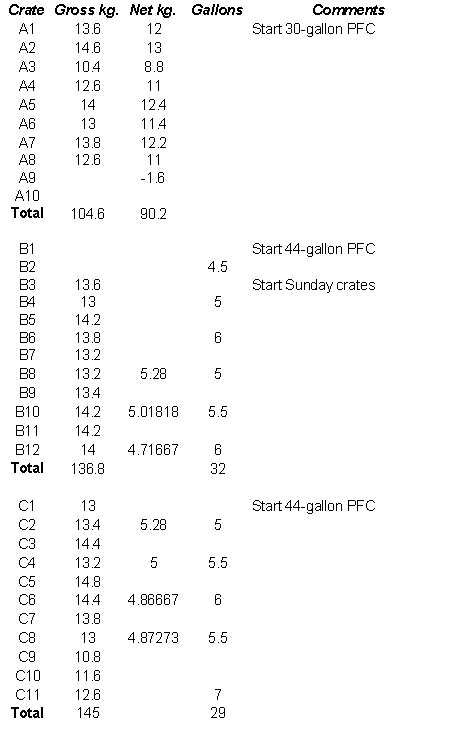

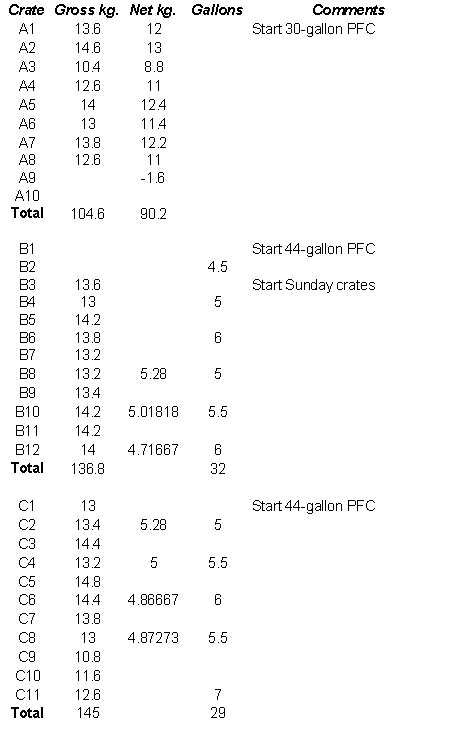

-- see spreadsheet

"Good judgement comes from experience, and a lot of that comes from bad judgement." -- Texas Bix Bender

New 44 gallon container from brian – See spreadsheet

Container A – 30 gallon capacity

contains 22.5 gallons

Container B – 44 gallon capacity

contains 32 gallons

Container C – 44 gallon capacity

contains 29.5

contains 6.5 gallons

We estimated that we have another 28 gallons of must from the full

row and two short rows left to pick. We pre-added 75 ml S02 for 28 gallons so

we will be able to add the yeast earlier tonight given the 6-hour wait after adding the SO2.

This turned out to be 4 gallons of SO2 too much.

| PFC | Sugar -Refractometer | Sugar - Hydrometer | Must Temperature |

| A | 24.8° | 25 | 70° |

| B | 23.6° | 23 | |

| C | 24.7° | 24.5° | 74° |

We have ants around the sink.

10:30 Calculated and weighed out yeast and Superfood.

Weight boats: .2 g. small

5.2 g.

Added Pasteur Red to the PFCs:

A: 22.5 g

B: 22g + 2 packages = 32 g.

C: 6 packages (=30 g.)

Added yeast dissolved (mostly) in 100

° F distilled water.Added Superfood:

A: 49.3 g.

B: 70.1g.

C: 64.6

Superfood package lists the amount as 4-8 pounds/1000 gallon. Starting from the lower end, 4 lbs/1000 gallons = .064 oz/gallon = .064*28.3 oz/gal = 1.8112 g./gallon.

We had 6.5 oz, while the lower end of the range required 5.376 oz. So we scaled the amounts accordingly.

Must is slightly murky plum. It tastes very good: rich grape flavor.

Room temperature: 64 (minimum 62, maximum 74)

10/6 8:45 a.m.: Room temperature: 63°

Punched must down.

| PFC | Sugar | Must Temp. |

| A | 23.5° | 68° |

| B | 23.2° | 73° |

| C | 25° | 71° |

We have ants around the sink.

11:30: Michael Murtaugh at The Wine Lab strongly recommends not waiting until Tuesday to add the Vinaflora Oenos. It will be more effective before the fermentation starts producing significant alcohol. He identified two alternatives: split the bacteria among the three PFCs or split among two PFCs and allowing the wine from those two PFCs to innoculate the third.

6:30: Swollen must with 6-8" cap starting to form. Significant froth freed from under the cap when we punch down. PFC A is noticeably less active.

Room temperature 64°

| PFC | Sugar | Must Temp. |

| A | 23.5° | 68° |

| B | 22.3° | 73° |

| C | 25° | 71° |

Added Vinaflora Oenos divided roughly 2:3:3 among the PFCs.

Added Leucofood: 3.2 g. to A, 4.6 g. to B, and 4.2 g. to C.

10/7 8:30am

Punched down. PFC B was about 4 inches from the top. All three PFCs

are active and have a firm cap, even A.

| PFC | Sugar | Must Temp. |

| A | 22.5° | 70° |

| B | 18° | 74° |

| C | 22.5° | 72° |

8:00 p.m.

Punched down.

| PFC | Sugar | Must Temp. |

| A | 20.5° | 70° |

| B | 16° | 76° |

| C | 21° | 72° |

10/8

8:30 a.m.Punched down. All PFCs have a 12-15" cap with great foam underneath, especially PFC C.

Room temperature 61° . Room has

varied little in temperature (61-64°

) since the start of this.

| PFC | Sugar | Must Temp. |

| A | 19° | 71° |

| B | 13.7° | 76° |

| C | 18.6° | 72° |

8:30 p.m.

Punched down.

Room temperature 68° .

| PFC | Sugar | Must Temp. |

| A | 16° | 71° |

| B | 12° | 74° |

| C | 17° | 72° |

10/9 8:30 a.m.

Punched down. Juice is now darker, more plum colored.

PFC A has less liquid per volume than the others. The cap on PFC C is 3" from the top (the only

Room temperature 64° .

| PFC | Sugar | Must Temp. |

| A | 15.2° | 72° |

| B | 9.2° | 73° |

| C | 15.2° | 72° |

8:45 p.m.

Punched down.

Room temperature 64° .

| PFC | Sugar | Must Temp. |

| A | 13° | 72° |

| B | 8° | 74° |

| C | 14° | 72° |

10/10 8:30 a.m.

Wonderfully rich smell of fementing grapes fills the room.

Punched down. PFC A has more liquid, similar to where the larger PFCs were yesterday. PFC B has even more liquid.

Room temperature 61° .

| PFC | Sugar | Must Temp. |

| A | 11° | 70° |

| B | 6° | 70° |

| C | 12° | 71° |

We are now punching down and measuring once a day.

10/11 8:30 a.m.

Room temperature: 60° .

| PFC | Sugar | Must Temp. |

| A | 8.8° | 69° |

| B | 3.7° , 4.2° * | 68° |

| C | 9.7° | 70° |

Measured 3.7° with the 0-30° hydrometer and 4.2° with the –5-5° hydrometer

10/12 8:45 a.m.

Room temperature: 58° .

Before moving must, the readings are:

| PFC | Sugar | Must Temp. |

| A | 6.2° | 68° |

| B | 2.2° | 67° |

| C | 7.5° | 66° |

After cleaning, we moved 8 gallons of must from PFC B into the 10 gallon PFC. We then transferred 4 gallons from PFC B to PFC C, mixed the must in PFC C well, and moved 8 gallons back from PFC C to PFC B. We then moved 4 gallons from PFC A to PFC B. We poured half of the must in the 10 gallon PFC into PFC C and half into PFC A. We leveled PFCs B and C. PFC A is slightly lower than in was before we started transferring must.

After moving the must, the readings are:

| PFC | Sugar | Must Temp. | pH |

| A | 5.6° | 67° | 3.17 |

| B | 3.8° | 67° | 3.18 |

| C | 6.5° | 67° | 3.19 |

The pH readings are consistent, but lower than Richard’s reading after calibration the night before of 3.37 for PFC C.

We measured TA:

22.9 miniscus after titration

-12.8 miniscus before titration

10.1 Þ TA = 1.01, which is very acidic like the pH

The must tastes very nice: sweet, tannic, with alcohol. Better tasting and more balanced than we remember last year.

Day |

PFC A |

PFC B |

PFC C |

PFC A’ |

PFC B’ |

PFC C’ |

Comments |

0 |

25 |

23.6 |

24.5 |

yeast added 10/5 10:30 p.m. | |||

0.5 |

23.5 |

23.2 |

25 |

10/6 a.m. | |||

1 |

23.5 |

22.3 |

25 |

p.m | |||

1.5 |

22.5 |

18 |

22.5 |

10/7 a.m. | |||

2 |

20.5 |

16 |

21 |

p.m | |||

2.5 |

19 |

13.7 |

18.6 |

10/8 a.m. | |||

3 |

16 |

12 |

17 |

p.m. | |||

3.5 |

15.2 |

9.2 |

15.2 |

10/9 a.m. | |||

4 |

13 |

8 |

14 |

p.m | |||

4.5 |

11 |

6 |

12 |

10/10 a.m. | |||

5.5 |

8.8 |

4 |

9.7 |

10/11 a.m. | |||

6.5 |

6.8 |

2.2 |

7.5 |

5.6 |

3.8 |

6.5 |

10/12 a.m. |

7.5 |

3.6 |

2 |

4.5 |

10/13 a.m |

To do today:

Clean stainless steel barrels, carboys, press, grape

crate, pump, tubing, fermentation locks with stoppers, and 20 gallon PFC for venacce.

Build rack for barrels from 2x4s..

Make SO2 solution for 30 ppm (plan for at least 60

gallons).

Punch down must and measure.

Move PFCs outside and mop floor.

Press into grape crate, pumping from there into the

stainless steel barrels and carboys.

Add SO2.

Collect two samples to send to The Wine Lab.

Put on fermentation locks.

Agree on schedule for checking fermentation locks.

We will add 30 ppm SO2 at pressing.

Stainless steel is very sensitive to acid, so you should not soak stainless steel barrels in either bleach or citric acid solutions. We learned this after soaking the stainless steel barrels in 1997 in a very weak bleach solution (1 cup in the 15 gallons of water) for 9 hours. Fermentation Settlement recommends Iodophor, which is designed for food containers, instead of bleach. We used citric acid solution briefly, sloshing it around, and drainng it right away,

Stainless steel barrels are very hard to work with. Water is heavy, and it very hard to get all the water out. We are dealing with that by filling the barrel completely with water, letting that sit for five minutes, emptying, filling the barrel again completely with water, and letting that sit for a half an hour..

Redwood Vineyard Management (707-857-1670) may have barrels. Ask for Tracy or Debby.

Thirteen days of skin contact this year. Long skin contact extracts the most flavor and color.

Determining ripeness: cf. FVtW p. 112.

Even 100 ppm. can be detected by a sensitive nose.

We have almost everything ourselves these first two years

because this time is all about our starting to learn the craft. Much of this journal

seems just common sense, but we fell short more times than we would like to admit on

basic, obvious steps and precautions.

According to FVtW, the wine needs more SO2 if the pH goes above 3.5.

According to FVtW, TA needs to be at least .55 for reds. TA above .9 unbalances a wine. TA has ten times more effect on the taste of the wine as pH, it is correspondingly more important to get the TA right.

The pH of a must will go up as fermentation progresses, by roughly .4.

Keeping the cap punched down also prevents mold or bacteria growing on the dried skins.

For the 44 gallon PFCs we use, the heat from fermentation does not get out of control. We have had a very steady tmust temperature this year.

Date all chemicals when they arrive.

Next year we need more shears and grape picking crates to make the harvest party effective.

Prepared 10ppm stock solution of so2 by adding 20g of potasium metabisulfide to 200 ml of distilled water.

6 hours cleaning and preparation, including getting materials and building rack for barrels. As usual, the preparation time dwarfs the execution time.

Hefting 44 gallon PFCs is very hard. Bigger is unacceptable.

figured out (finally) how to use the press

effectively. we now seem to be getting again as much press juice as we got in free

flow. much higher yield from must than last year!

30ppm so2 (30ml) in all three 15.5 gallon stainless.

30ppm so2 (10ml) in both 5 gallon carboy..

30 ppm so2 (2ml) to almost full 1 gallon jug.

poured 1 gallon jug to 2 sample jars, 1/2 gallon jug, and

into two wine bottles to drink.

Nitrogen: 12 psi, 1000 psi

Trace SO2 added to fermentation locks.

10.21.97 8:20 a.m.

room: 60?

labelled stainless steel kegs D, E, F

Clinitest (to check residual sugar levels)

D .5 degrees brix

E .4

F .4 grainy texture

G .4

H .4

10/29/97 See the Wine Lab report

11/22/97

Started malolactic fermentation test.

Room temperature range since last time: 52-63 degrees

Sugar (Clinitest): 0.4 for all containers (maybe a little

lower).

11/29/97

Malolactic conversion test: All samples showed very distinct tartaric acid splotches, no perceptible malic acid splotches, and weak lactic acid splotches (Keg D’s lactic blotch was a bit more distinct). See the actual results

The weakness of the splotches this year tells us that next year we should put at least a second drop of wine on the chromatogram paper.

Richard calibrated the pH meter. There seems to be a

problem with the probe in that the 4.01 and 7.00 buffer solutions measured 6.86.

1/3/97 12:30 p.m.

Room temperature: 51 degrees. Temperature range since last reset: 42-64 degrees.

We do not have a good understanding of two chemical

reaction curves:

When the SO2 reacts, which tells us how much SO2 to add

at this stage of the wine.

When the calcium carbonate reacts to reduce the

acidity, which tells us when to send samples to The Wine Lab.

Strategy:

Today: Calibrate pH meter with new probe, add 20

ppm SO2, and add calcium carbonate.

Monday: send Fred message about the chemistry.

1 or 3 weeks from now (depending on Fred's answer):

send wine samples to TWL.

When get TWL results: rack wine, including into one oak

barrel.

Calibrated pH meter.

Our initial measurements of Keg F and Carboy H were 3.09

and 3.11, respectively. We stirred, took a bigger sample, and remeasured, to get the

measurements above.

Our initial pH measurements of Keg F and Carboy H were 3.09

and 3.11, respectively. We stirred, took a bigger sample, and remeasured, to get the

following pH measurements:

Keg D: 3.18

For potassium carbonate, following wine lab report of 10/29/97, we will add .08 g/ 100 ml in order to correct the pH to 3.43 -- equivalent to 3.04 g per gallon. We have 55 gallons. We will mix 167.2 g in 110 ml of distilled water, then add 30 ml to each of the 15.5 g kegs and 10ml to each of the 2 5 gallon carboys.

5.3 g. (for boat) +167.2 g. = 172.5 g.

330ml of potassium carbonate solution prepared. Added 90ml to each of 15.5g kegs and 30ml to each of 5 g carboys. Heard distinct fizzing in the kegs, not in the carboys

20 ppm potassium metabisulfite = (20/50) *.38 g./gallon *

55 gallons = 8.36 g

8.36 + 5.25 13.6 g.

Added K2SO5 to 55 ml of our wine. Stirred with maagnetic stirrer.. Had some crystals. Added 55 ml. more wine and stirred. Crystals dissolved some, but some left. Removed biggest crystal. Added 30 ml. to each kegs and 10 ml. to eaach carboy.

Vapor lock on Keg H was hard to seat and vapor lock on keg D filled with wine because of escaping gas.

2/15/98 4:30 p.m.

We still have not racked the wine, which potentially poses two problems: extended contact with the lees resulting in bitterness and not enough aeration.

Plan:

Today: Take samples from all 15.5 gallon kegs and one

of the 5 gallon carboys to send to The Wine Lab.

Two weeks from now: adjust based on TWL's

recommendation and rack first into two primary fermentation containers and then rack again

back into the original containers.

Two weeks after that: Rack Keg D (15.5g) into oak

(15.5g) and rack the others into stainless steel.

Tasted Keg E. Nose and taste have mustiness very much like last year's (due to same cause? lack of aeration?). We will get another opinion.

Tasting kegs

Overall, at least a 'B'. E is an 'A'.

More body and more tanin than 96.

High glycerine ("legs"). Glycerine is slightly

sweet.

Glycerine higher because both fruit sweet and Pasteur red

produces more. (Commercial wineries do not use Pasteur red because it foams higher.)

D:

E: most body, distinct cabernet character

F: flatter, slightly more astringent

P: close to, almost as good as E

Action Item: buy white lithium food grade grease to use on

all metal parts (like on the wine press).

Action Item: get corks for kegs.

Reinserted fermentation locks (with trace SO2 ) into newly filled, and blended D, E, and the Pepsi container.

Cleaned suction tubing by running SO2 water thru. The intent is to use this to keep mold from growing while the tubing is drying.

Next action: check barrel for taste in 6 weeks.

high-low thermon=meter: 45-66 degreees

room temperature: 52 degrees

Thick mold all over cork and barrel near cork,

feeding on wine overflow.

White mold growing on oxidized copper color mold.

Created strong K2SO5 solution (half yellow teaspoon per 150 ml. Soaked new barrel bung in solution. Scraped most mold from area cleaned area with water. Cleaned area with K2SO5 solution so no mold could fall into the barrel. Removed old cork immediately replaced with new cork. No mold in barrel! Cleaned molded barrel bung with K2SO5 solution and returned to un-used barrel to keep inside of empty barrel from air-born uglies.

5/2 5:00pm

R decanted a bottle of '96 at 1:00 today, swirled it around,

and filtered it twice. It was very cloudy. The earthiness/ether smell was less

pronounced. Good fruit in nose and taste. Not much interesting in the

taste Medium body. Whatever there is in the taste hits the center of the

pallatte.

Ordered a 132-gallon variable capacity barrel from Napa Fermentation Supplies.

Wine seaped out of oak barrel again, with mold starting to grow again. Conclusion: the barrel is too full. We will take some out with today's tasting

The room is big enough for one more harvest, but will be uncomfortable after that.

Do we need to buy a 60-gallon barrel. R: estimated 30% more volume next year. D estimates 100% more next year. Decided not to buy any more barrels now

Barrel questions: is there a better bung to use than the wooden one? is there a "proper" tool to use to remove the bung from the barrel?

Checked level of wine in barrel relative to bung. Bung is NOT touching wine -- 1 inch separation, but we are still seeing wine leakage around the bung - why and how????

Tasted wine from each of oak barrel and Pepsi container.

Unoaked:

clear; good Cab color; good legs

Oaked:

same visually

Action items:

Register for wine sensory class.

5/10 5:30

Great smell when we cracked open the Pepsi container.

There is a line of mold around the cork on the oak barrel. Cleaned as last two times.

5/17/98

Mixed new citric acid.

Noted that use of SO2 to clean siphon tubing worked! Tubing 8 weeks later is perfectly clean -- no signs of mold.

Need more Wine Lab sample bottles.

Plan for today:

Clean tubing. Rinse new barrel.

Transfer contents:

Keg D to new oak barrel K.

Oak barrel J to Keg D.

Keg E to oak barrel J.

Top off from Pepsi container or hold exra as needed.

If significant sediment at bottom of Keg D, rinse Keg D.

Transfer contents of Barrel J to Keg D.

5.23.98 Sunday 6pm

Per recommendation of Demptos, we are attempting to see if our leaky barrel will seal itself by expanding, given an initial period of liquid contact. Filled that barrel with water and added 1 tbl of K2SO5 and 3 tbl of citric acid and sealed the barrel. We will check each day for the next couple days to see if the leak stops. After filling, I can see seapage from the front right side of the barrel at a seam.

June 6 4:30

Temperature 64 degrees. Range since last time 52-68 degrees.

More wine has seaped out of Barrel J. Serious mold has grown around bung. New barrel K was withstood the seapage test, and we will proceed to use it.

Plan for today:

clean mold from Barrel J bung.

cleaning around bung of Barrel K with K2SO5

plan for tastings of each oak barrel

clean and transfer from Keg X to Barrel K

Plan for tastings:

Strategy under-oak both oak barrels and ignore for now the 4+

gallons in Pepsi container.

We will taste contents of Barrel J (older oak barrel) roughly

5-6 weeks after put in barrel (5/17). Target Wednesday June 24 6:30 p.m. We

will take samples this day.

We will taste Barrel K (new oak barrel) after roughly 5-6

weeks. We need to adjust this when we taste Barrel J. Target Saturday July 10.

Lesson: Always label glasses.